Sandwell uses Additive Manufacturing to produce tooling for Shot Peening and Surface Finishing. The ability to produce tooling quickly and match to complex shapes has considerably improved both turnaround times and repeatability.

We also work on customer parts that have been produced by many of the 3D additive methods to improve surface finish. Sandwell has many years’ experience in improving the surface finish of metallic components produced by this method. We have a range of equipment and machines that allow us to work on almost any material and shape. With the use of surface measuring equipment we can quickly feedback process data to meet customer requirements.

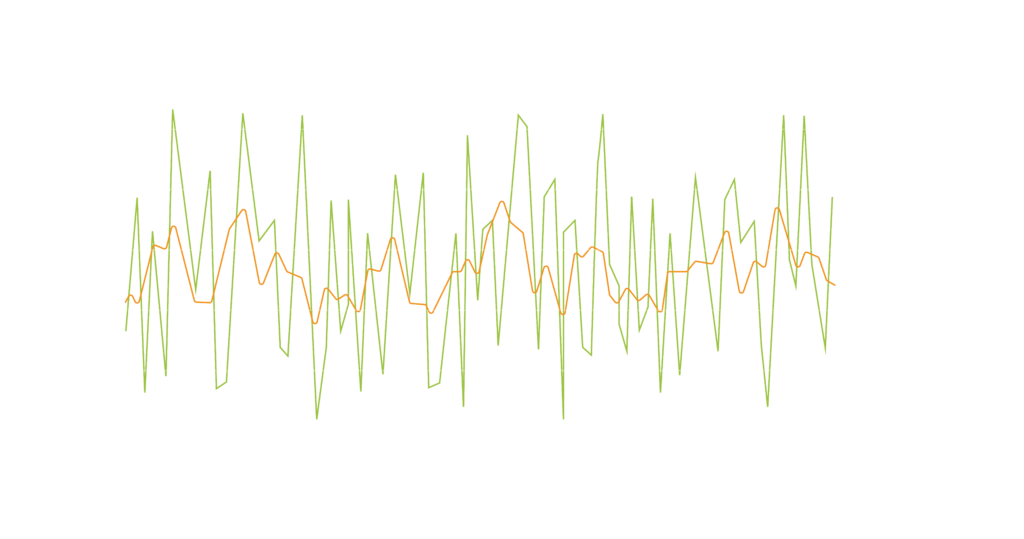

Each additive manufacturing process has its own characteristics and often a high build rate means a coarser surface finish.

Of the Powder Bed Fusion methods Selective Laser Melting SLM appears to produce the best surface finish with Electron Beam Melting EBM producing a coarser finish. Some of the Blown Powder Systems are now also providing an improved surface finish.

All of these additive manufacturing methods require a post process finish to provide a satisfactory end product. At Sandwell we have many years of experience finishing additive manufactured parts. It is by no means easy and presents many challenges. One of the many advantages of additive manufacturing is that much more complex shapes can be produced which is great for the designer and end user but it does make the surface finishing a complex operation and often results in multiple stage processing.

A good starting point with additive components is an initial rumbling process. This will help to break down the bulk of the surface although it may not always be so effective on the finer detailed areas.

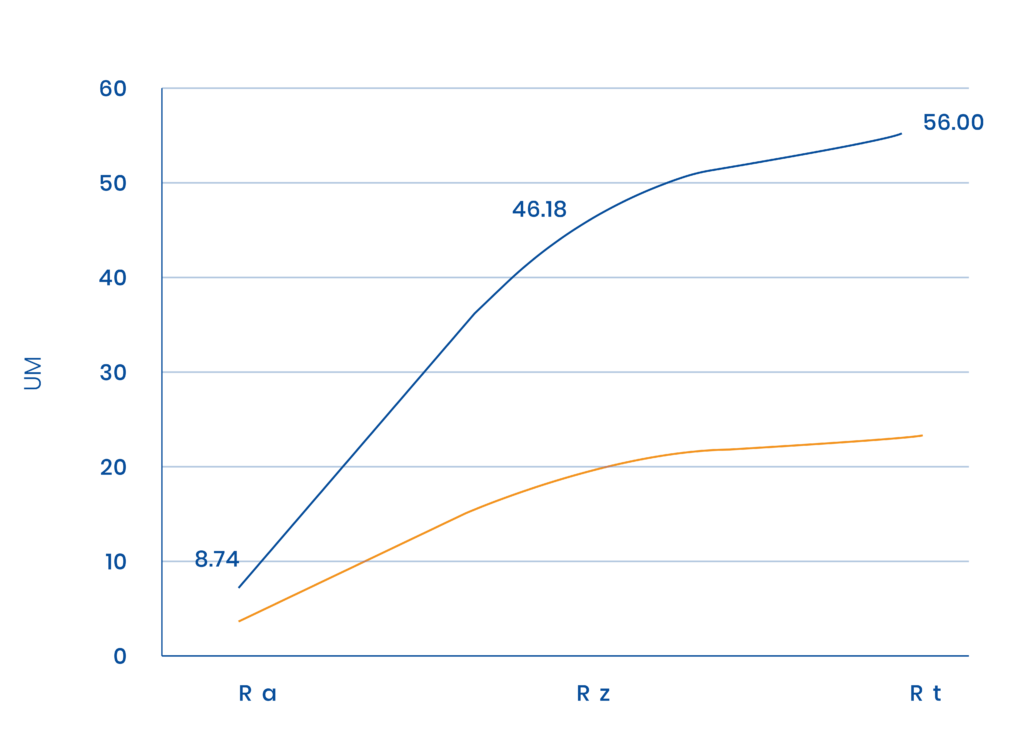

A lot can be read into the data hence it is important for in process monitoring.

Call us on +44 (0) 1327 350205, send an email to sales@sandwell-uk.com, or leave your details here: